Melbourne Tram Museum

- Follow Melbourne Tram Museum on Twitter

- Follow Melbourne Tram Museum on Facebook

- Follow Melbourne Tram Museum on Instagram

- Follow Melbourne Tram Museum on Pinterest

- Follow Melbourne Tram Museum on Tumblr

- Subscribe to Melbourne Tram Museum's RSS feed

- Email Melbourne Tram Museum

Building the W class tram

A shorter version of this article, published to commemorate the centenary of the first W class tram, originally appeared in The Bellcord No 60, December 2023.

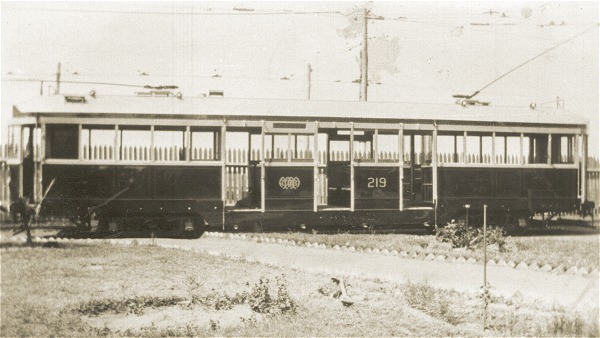

Photograph of the incomplete W class No 219 at Preston Depot (Thornbury), date unknown but probably December 1923. The tramcar does not yet have windows or step boards and is fitted with long poles from a Birney car. Note the early version of the M&MTB monogram.- Photograph from the Keith Kings collection, Melbourne Tram Museum.

The focus in this article is on the construction of the very first W class trams – namely those with three equal doorways in the drop centre of the car, with seats in the centre section facing the middle of the car. Tramcar W380 at the Melbourne Tram Museum is representative of this layout.

To convert the cable system to electric traction, the Melbourne & Metropolitan Tramway Board (M&MTB) needed an easy-to-build, cost- effective tramcar of a standard design. The W class tram was the solution. Its drop centre provided a lower step height than the earlier straight sill (flat floor) Q class trams built by the Board. The W class tram entrances were all located in the centre of the car so the conductor could easily observe the doorways. In comparison, the earlier Prahran and Malvern Tramways Trust (PMTT) and the Hawthorn Tramways Trust (HTT) drop centre cars had additional doors at each end that were harder to observe (as described in The Bellcord No 53).

In City services, such as along Swanston Street, rapid loading and unloading are essential. The initial layout of the W class trams with three equal sized doorways only partly achieved this. The later W2 class layout replaced these with a smaller centre doorway and two adjacent doorways wide enough for two passengers to pass through at the same time, improving loading and unloading. Other improvements included better destination signage, and use of four motors as in the PMTT-designed Lclass and the VR trams. The new W class tram had a passenger capacity of about two cable car sets, consequently saving in crew manpower.

The PMTT L class bogie tram, with its curved sides, detailed interiors and greater weight (19.5 tonnes as built, compared with a W class weighing about 17 tonnes), would have been considered expensive as well as using more energy. The lighter weight for the W class was achieved by designing the tram with flat sides and a simpler structure.

The Board approved the general design of the tram on 27 July 1922.

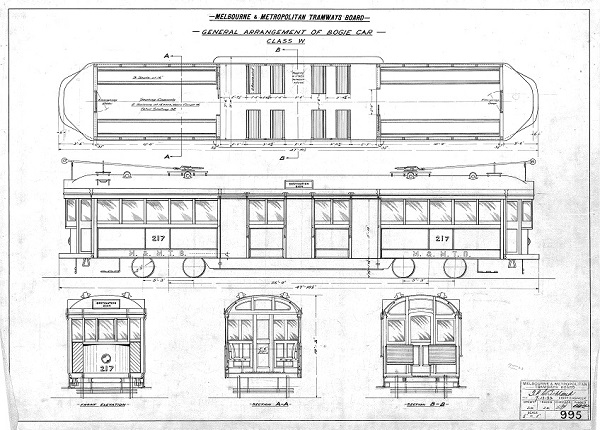

The earliest W class drawing in the Museum’s drawing collection: R995, dated 7 December 1922. The tramcar is shown as No 217. The drawing was created at about the same time as the M&MTB’s purchase of the two X class Birney trams which became Nos 217 and 218. Click to view a larger image.- Drawing from the collection of the Melbourne Tram Museum.

The Argus of 27 April 1926 reported on the chassis or the underframe of the tramcar body:

In one place are the rough girders which form the “backbone” of the chassis and the undressed timber which is fashioned into the frames… One of the first parts of the process of carbuilding consists of laying out the heavy iron girders which form the chassis. Each of the two main side girders is built in three sections, which are secured by special angle brackets and joined in the completed chassis by a series of cross girders, giving the finished frame surprising strength and rigidity. Of next importance to strength is lightness, and, with a view to reducing running costs and depreciation expenses, a great deal of thought has been devoted to the removal of every possible piece of metal from the tram frame.

The Drawing Register shows the timescale of the tram’s development with body details, truck or bogie drawings, brakes, lifeguards and schedules (lists of parts, components, etc). By April 1923, many detail drawings had been completed showing tram sections, seats, body metal work, motor supports, outline of equipment components and various body components. From November 1923 to early 1924 drawings were still being prepared for the handrails, sand hoppers, door runners and the many small brackets. These were probably drawn from workshop sketches used to make the items in order to fully document the tramcar construction and for the contracted body builders.

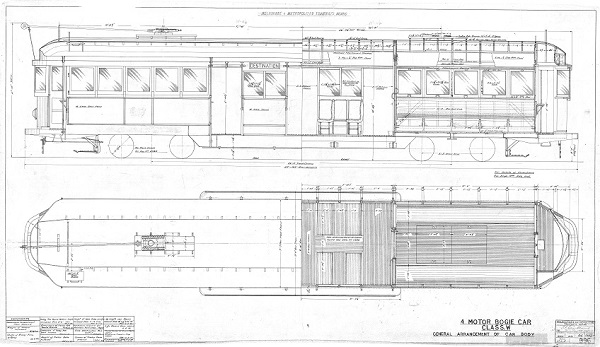

The second earliest W class drawing in the Museum’s drawing collection, R996, dated 26 January 1923, better represents the W class body than does R995, although over the next few years there were 14 changes to this drawing. These were mainly around the trolley pole location and the size of its base, as well as documenting the evolution of the body from one with roof ventilators to a ventilated roof. Click to view a larger image.- Drawing from the collection of the Melbourne Tram Museum.

Drawing R1066, originally dated 22 May 1923, lists the size and type of timbers to be used in the body: Oregon, blackwood, white Baltic pine, Tasmanian red myrtle, plywood, Queensland maple, hoop pine, mountain ash, stringybark and celery top pine.

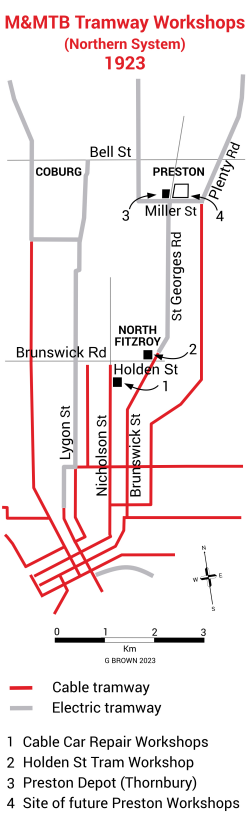

Tramcar bodies

The first two W class trams, 219 and 220, were built at the rear of the cable car house on the corner of Holden Street and St Georges Road, North Fitzroy. This was prior to the completion of Preston Workshops in 1925 to 1926. Background on the use of this location for car building – covering a repeat order of Q class cars before the Ws – is described in The Bellcord No 49. It was not until 1926, when all the “shops” were constructed, that a W class tram was fully built at Preston Workshops.

Location of M&MTB workshops, 1923.

Location of M&MTB workshops, 1923.- Map by Geoff Brown.

The Holden Street car builders operated in very cramped conditions. The Board leased another building in Holden Street in June 1923 for use as a carpenter’s shop, to make some of the many wooden components of the W class tramcars. The steelwork for the chassis was made at the North Fitzroy Cable Car Repair Shops in Nicholson Street – which had the facilities to undertake the steelwork fabrication – and was then transported to North Fitzroy Tram Works. Specialised woodworking and steel working machinery was purchased by the M&MTB and later transferred to Preston Workshops.

The 1923-24 Annual Report advises that the completed cars were transported to the Preston Depot (Thornbury) for painting and electrical equipping. The report also records that machining of the woodwork for construction of new electric rolling stock was carried out at the Cable Repair Shops as well.

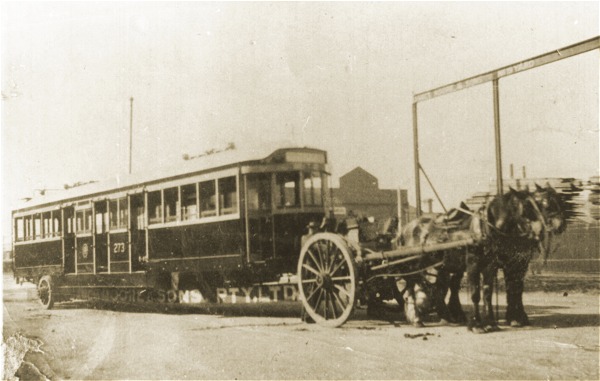

A small “workshops locomotive”, No 8A, was built to transport the unfinished tramcars to the Preston Depot (Thornbury) for painting and electrical equipping.- Early 1940s photograph from the Peter Duckett collection, Melbourne Tram Museum.

Contract body builders

The North Fitzroy Tram Workshop could not achieve the level of output needed to meet the target of 120 tramcars ready for service by September 1925. Tenders were advertised Australia-wide during mid-June 1923. The tender for 60 bogie car bodies was awarded at the 26 July 1923 Board meeting to Holden’s Motor Body Builders Limited of Adelaide for £82,980 (£1383 each) with the proviso that the M&MTB’s Chief Engineer (T.P. Strickland) negotiate with James Moore & Sons of South Melbourne for additional cars. The other tenderer was Pengelly & Co of Adelaide. This tender resulted in questions raised in Parliament, as well as in local newspapers, as to why the work was not being done in Victoria, demonstrating the parochialism that remained from the days of Victorian industry protection prior to Federation. The Ballarat Star of 23 August 1923 reported that the first four sample cars from Holden (Adelaide) were to be delivered by December. The first Holden built car – 279 – entered service in April 1924.

Tram body being built at Holden’s Motor Body Builders in Adelaide, showing construction of the chassis. The make-up of the chassis of a W class tram can also be seen in the training room at the Melbourne Tram Museum.- Photograph courtesy of Dr John Radcliffe, in the collection of the Melbourne Tram Museum.

During August 1923, negotiations concluded with James Moore & Sons to provide 30 cars, given in the Minutes at £1429 per car including contingencies, with the first car to be delivered in six months and then two per month. Another contract for 30 W class car bodies was subsequently awarded to this company.

M&MTB W class No 273 leaving James Moore’s yard in South Melbourne, late 1925. Other photographs of W class trams on a jinker show three or more horses being used.- Photograph from the Bob Lilburn collection, Melbourne Tram Museum.

Tram bogies

Each tram requires two bogies, or trucks, complete with frames, axles, bearings, wheels and brake rigging. The bogie, later known as the No. 1A truck, was modelled on the USA Master Car Builders High Speed Interurban Truck. The Minutes do not record whether the M&MTB purchased a licence and drawings, or just copied them.

Drawings R1006 and 1008 (both dated April 1923) and related drawings detail the many parts that had to be first made and then fabricated into a completed bogie ready to be fitted with a motor.

It was recorded in the 1923-24 Annual Report that:

Repair [cable tram] Shops have constructed the trucks required for all the new drop centre bogie cars, and the underframes, body iron work and hand-brake gear for the cars built by the Board.

To facilitate this work, additional machinery was provided.

The Repair Shops did not have the capacity to build all the bogies required to meet the M&MTB’s tramcar production schedule. Tenders were called during September 1923 for 30 pairs or 60 bogies. The contract was awarded to Perry Engineering of Adelaide, at a cost of £8940 or £149 per bogie. Other tenderers were the Government Dockyard Newcastle (submitting a tender with the – non-compliant – NSW Government Tramways bogie as well as the MMTB model), G F Sewell of Footscray, Thomson & Co of Williamstown, Noyes Bros, Gibson Battle and Brill Co Philadelphia offering a choice of the Brill 77E1 or Brill 27 MCB1.

Axles, wheel centres, tyres (that go on the wheel centres), and forging of equalising bars were tendered out and awarded to Australian-based contractors.

M&MTB W class No 317 on the traverser at Preston Workshops, circa October 1925..- Photograph from the collection of the Melbourne Tram Museum.

Electrical equipment

In the 1920s, suppliers such as the international manufacturers General Electric and Metropolitan Vickers (the successor to Westinghouse UK) supplied a complete set of electrical equipment. Described in the Minutes as “four-motor equipments”, this included four tramcar motors, two controllers, switches, circuit breakers, lightning arrestors, trolley poles, and a set of resistance grids, but excluded the compressor and related equipment.

The first set of 60 were split between Metropolitan Vickers and Australian General Electric (“Australian GE”), a subsidiary of General Electric USA. The other tenderers were English Electric, Gibson Battle as agent for Brown Boveri, and British General Electric (“British GE”). The Board ordered the MV101A motors with controllers from Metropolitan Vickers and BTH 265 motors with K35JJ controllers from Australian GE. The cost for each four- motor equipment set from Metropolitan Vickers was about £883 with import duty of 27.5% included and a delivery time of 15 to 27 weeks. Each set from Australian GE cost £881 with 27.5% duty and a delivery time of four and a half to seven months. It appears a duty of 40% was imposed on the controllers as they would have come from the USA, rather than from the UK.

Import duty was levied by the Federal Government. It was a complex system, designed to give Australian industries some protection. According to a brief history of our tax system, published by The Treasury:

Although the states retained control of land and income taxes, customs and excise duties were by far the greatest source of taxation revenue at the time of Federation.

The Board employed a customs advisor to assist in processing the paperwork in a timely manner.

When the next order for “four motor equipments” came to be awarded at the end of 1923, Metropolitan Vickers (20 sets) and Australian GE (30sets) were again recommended along with English Electric (10 sets) who would have provided some locally made equipment. In March 1924 the Chief Engineer changed his recommendation for purchase to 35 sets from Australian General Electric and 25 sets from Metropolitan Vickers. The Chief Engineer also requested authority to accept an offer from Australian GE for K35JJ controllers to replace rejected controllers from Metropolitan Vickers. This is the first time that such an issue was raised with the Board.

The Victorian Minister for Public Works had to approve such purchases. His office asked for further data during May 1924 and particulars regarding supplies being obtained from Australian manufacturers. It was not until late July that the Minister gave approval to order 20 four motor equipments with General Electric control, 40 General Electric controllers and circuit breakers and 30 four motor equipments complete from Metropolitan Vickers except for controllers and circuit breakers.

Advice was received from the Comptroller General (Customs), that the Federal Minister had decided to admit 10 four motor equipments manufactured by English Electric under tariff item 404, duty free. This was conditional upon the Board ordering 40 motors (10 equipments), 20Lightning arrestors, 20 trolleys, 10 sets of Resistance grids and spares from English Electric. These were Dick Kerr 34A model motors and Q2G1 controllers.

The first and second tender schedules do not detail the type of controller Metropolitan Vickers offered at the time. Drawing R1204 (14 December 1923), held by the Museum, shows the wiring diagram for a Metropolitan Vickers No MV T4A controller with rheostatic magnetic braking. With this type of electric car brake (which is fitted to Z class trams) the retardation is caused by the drag of track magnets on each rail when energised by current from the car motors acting as generators. The equivalent drawing for the General Electric K35JJ controllers is dated 1 December 1923.

Air brake equipment

The first tender for air brake equipment was awarded to Australian GE in late May 1923. The other tenderers were English Electric (Allis Chalmers), British GE and Westinghouse Brake.

The second tender for 60 sets was also considered by the Board at the last meeting of 1923. This was interesting in that Australian GE was awarded the work for compressors and air tanks, but the brake valves, handles, drain cocks and safety valves were awarded to Matthew Coates acting as an agent for Westinghouse. Duty on such equipment was 40% with a three to four month delivery. The cost of this equipment from both manufacturers totalled £9542 including spares. Each set cost about £154 excluding spares. At the time the brake valves were of the manual lap type, not the self lapping type later fitted to Melbourne W class tramcars.

Other equipment

The Board also considered tenders for wheel sets and the manufacture of 120 sets of tramcar blinds. The latter was awarded during October 1923 to R F Benson, as agent for the Curtain Supply Co USA at £45 each.

How much did it cost?

It is very difficult to undertake a price comparison with the 1920s – even if inflation, labour and materials indices are taken into account, there are very few current components that are directly equivalent to those used in the 1920s. Back in the 1920s, a draftsman was paid £7 per week, A.G. Monsborough – later to become the M&MTB Architect – was initially employed as the leading architectural draftsman at £9 per week. A Ford truck with a cover to carry the cash from depots to Head office and then to the banks was purchased for £250 in September 1923, and a single-seat Wolseley was purchased for £485 in February 1923. In August 1923, the Board purchased a 20.88HP 6 cylinder “Loraine Dietrich” car offered by Bevan Bros Tucker for £795.

However axles can be compared with current prices. In 1923, the MMTB purchased axles from Commonwealth Steel for £8 6s 7d each. During 2022 the tramcar section of the Auckland-based Museum of Transport and Technology purchased axles from a local New Zealand manufacturer for about NZD4,000 each. In 2023 an estimate for Melbourne trams was about $6,000 per axle.

At the Board meeting of 9 October 1922, approval was given for the building of 30 bogie cars at an estimated cost of £105,000 or £3,500 each. The per-car cost across the various tenders was £2,674, comprising:

| Body (Holden’s price – including painting) |

£1,383

|

| Motor equipments (including duty) |

£880

|

| Bogies (Perry Engineering) |

£150

|

| Air brake equipment (including duty) |

£154

|

| Blinds |

£45

|

| Wheels – axles, centres and tyres |

£62

|

| Total |

£2,674

|

A summary of the costs of the tenders can be found here.

Assuming that the Board’s own cost of building the body and trucks at Preston Workshops was comparable to that of the tenders, that suggests the final set of activities – wire, assemble and install brakes and other equipment and put the car into service – would amount to around £626 per car. The actual cost had not been reported in the Minutes up to September 1924.

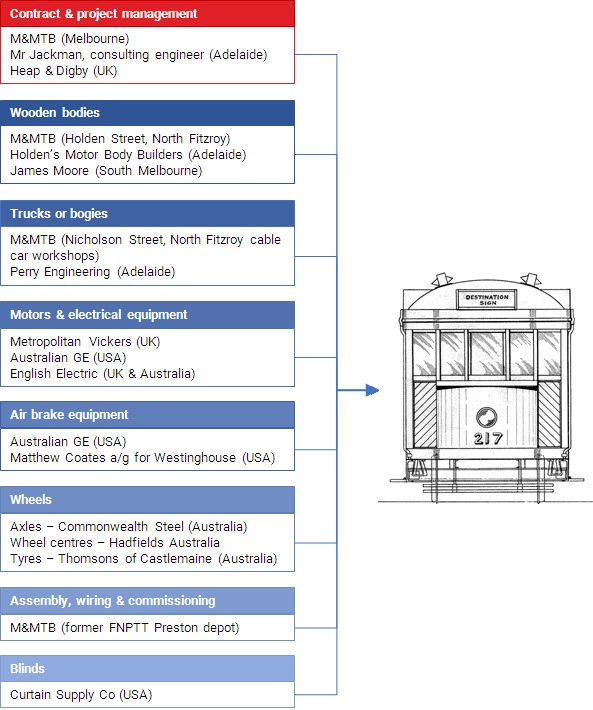

Extract of original 1922 Drawing R995 showing W class bogie car No 217 with schematic of suppliers, contractors and M&MTB groups involved in building the W class tramcars, as at 1923-24. Note that Drawing R995 was created at about the same time as the M&MTB’s purchase of the two X class Birney trams which became Nos 217 and 218.

The rollout

The Argus of 20 September 1923 noted that:

The designs and drawings for a new type of drop-centre bogie car was [sic] finished, and the construction of one sample car was almost completed. Altogether 20 had been commenced. Contracts had been entered into for the construction of 90 car bodies of the same design, also for trucks and electrical equipment.

At the 30 August 1923 Board meeting, the Chief Engineer advised that 120 authorised bogie cars would be completed by September 1925. An analysis of the in-service dates shows that by the end of August 1925, 99 cars had been built with a further seven completed during September 1925.

| Year |

W class trams completed

|

|---|---|

| 1923 |

2

|

| 1924 |

60

|

| 1925 |

80

|

| 1926 |

51

|

| 1927 |

7

|

| Total |

200

|

As part of any rollout of new equipment there are many other considerations to be managed, such as depot space, training of drivers, conductors and maintenance staff, and ensuring sufficient spare parts in store. Spare parts for both motor controllers and air brake equipment were ordered at the same time as the contracts were placed.

Commissioning the first two: Nos 219 and 220

Information about the commissioning and formal testing of the first tram is slight. So far no relevant reports have been located in Trove or in the Public Records Office Victoria. Commissioning and some training of the Trainers, would have commenced as soon as possible, using the tracks out of Preston Depot (Thornbury), in particular in St Georges Road.

It would appear that late delivery of motor control equipment and other parts was a significant factor in delaying the rollout for service to the public. The tramcar card for tram 219 shows it being put into service with “35HH controllers borrowed from the Vic Railways, 8" Cylinder and Trolley bases off St Louis (Birney) car. Own controllers (K35), 10" brake cylinder (US bases removed (February ’24))”. An 8 inch or 200mm diameter cylinder would have meant the tram had a lower braking capacity than those fitted with a 10 inch or 250mm diameter cylinder which was standard for the rest of the new W class fleet. The card shows that it was transferred from Preston incomplete on 8 December 1923. Tram 220 was also sent incomplete to Malvern Depot just before Christmas 1923.

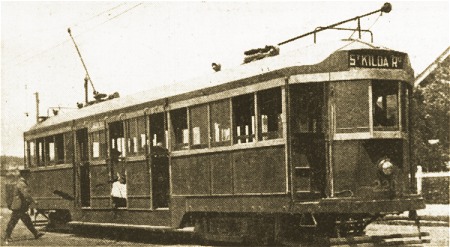

Photograph of the newly built W class No 220 in The Sun News-Pictorial,

5 January 1924.

Photograph of the newly built W class No 220 in The Sun News-Pictorial,

5 January 1924.- From the Keith Kings collection, Melbourne Tram Museum.

The entry into service of the two new W class cars was noted in Melbourne newspapers. From The Age on 4 January 1924:

To meet the special traffic requirements of the metropolis the Tramways Board recently put in hand the design and construction of a large number of electric bogie ears in its own workshop at Fitzroy. Two cars have been completed and put into service at Malvern. These cars embody several interesting features, and as the work of construction is being pressed forward they will provide much relief to the travelling public during periods of crush loading – in the morning when business people are making for the city, and in the afternoon between 5 and 6.30 o’clock, when they are returning to their homes. Not only have the cars been designed by the board under the direction of the chief engineer (Mr. T. P. Strickland), but with the exception of certain electrical equipment, the new cars both as to material and labor are Australian throughout.

The car has a seating capacity of 52 passengers, and is 47 feet 10½ inches long over all. There is a saloon at each end, having longitudinal seats, whilst the centre part, in which cross seats are provided with passage way between, is available for the use of smokers. An important feature of the design, and one which will be appreciated by passengers, is the drop centre, which facilitates boarding and alighting from the car with ease and comfort. The average height of this step is approximately 1 foot and when this is compared with other standards, passengers will at once appreciate the advantage of the reduced height of the platform from the surface of the road. Each of these cars is equipped with four 40 h.p. motors – power sufficient to handle the heaviest load and operate the cars over the steepest grades on the system. Both air and hand brakes are provided, and are so arranged, that the operator has the greatest command over the car under all conditions. When required, sand is applied to the rails by compressed air.

Passengers will find the new destination sign, used for indicating the car route, and which is built into the car, and forms part of the frame work, an improvement on those now used on the road. Destination signs in the front and rear of cars are supplemented by side route indicators, which will help passengers to pick immediately the car they desire. This is the first instalment of the board’s latest car building programme. In all 120 of these cars are being built, and it is expected that within the next year or two the demand for rolling stock will be over taken by the output from the board's factory.

The Argus reported on 8 January that the two cars were in service at Malvern. On 11 January 1924 The Prahran Telegraph reported that the two cars were in service on the Glen Iris line and gave a detailed description of the tramcar itself and its attributes..

After these two cars entered service, there was a gap of about three months before the next three entered service during March 1924, again working from Malvern Depot. New tramcars entering service then became much more regular, for example 12 new cars were put into service during September 1924.

Conclusion

The provision of 120 new W class tramcars during the period 1923 to 1925, followed by another 80 finished by early 1927, was just part of a much bigger project. This was to convert St Kilda Road and Swanston Street to electric traction with new track, depots and substations, then roll out the tramcars as they were built. It also encompassed convincing the City of Melbourne that overhead span wire construction, rather than centre poles or even conduit, was the way forward.

The Chief Engineer, Mr Strickland, oversaw all this work, very much like George Smith Duncan oversaw the installation of the cable tram system. Although the new trams subsequently had their central or drop centre section modified to a form that better suited Melbourne’s conditions, the W class tram was very successful. It provided a model that was to evolve to the W7 and then the W8 type. The project had a few issues like all projects do, nonetheless it met the production target needed for the cable tram to electric conversion.

Postcard showing Swanston Street, c1926 and W class No 328.- From the Ron Scholten collection, Melbourne Tram Museum.

Acknowledgements

Many thanks to Geoff Brown, Noelle Jones, Mal Rowe and Brian Weedon, as well as many others who contributed to discussions about drawings, reports and tramcar cards.

Bibliography

Norm Cross (1971) “The W2 Story: A Short History of a Class”, Running Journal, June 1971

Norm Cross, Dale Budd and Randall Wilson (1993) Destination City (Fifth Edition), Transit Australia Publishing

Keith Kings (1973), “A salute to our veterans”, Running Journal, December 1973

Keith Kings (1979-80), “60 Years of the M&MTB”, Trolley Wire, in three parts over December 1979, February 1980 and April 1980

F N Maclean (1932), “Latest Types of Tramcars in Melbourne, Adelaide and Brisbane”, reprinted in Trolley Wire, October 1986

Melbourne & Metropolitan Tramways Board, Annual Reports 1923 to 1927

Melbourne & Metropolitan Tramways Board, Summary of Materials purchased under special contracts 1919 to 1969

Public Record Office Victoria, Melbourne & Metropolitan Tramways Board Minutes, Volumes 1 to 4, November 1919 to September 1924, VPRS 7765

John Radcliffe (1988), “Body by Holden”, Trolley Wire, February 1988

The Age (1924), New Tramcars Designed and Built in Victoria, 4 January 1924

The Argus (1923), Tramway Surplus, 20 September 1923

The Argus (1924), New Electric Tramcars Builders Busy at Fitzroy, 8 January 1924

The Prahran Telegraph (1924), New Tram Cars Designed and Built in Victoria, 11 January 1924

The Sydney Morning Herald (1923), Tenders, 13 June 1923.

The Treasury (2006), A brief history of Australia’s tax system, 4 September 2006

Geoff Warburton, W class overhaul and work data sheets